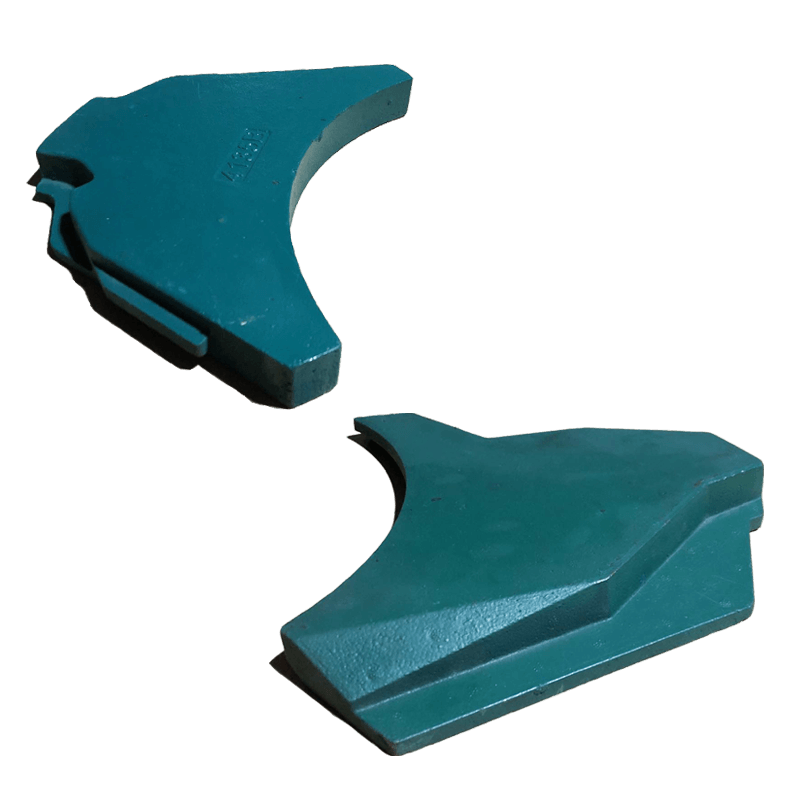

What is the upper and lower wear plate?

A VSI (Vertical Shaft Impact) crusher is a type of impact crusher that uses a high-speed rotor with a crushing chamber that is lined with wear-resistant material. The upper and lower wear plates are two of the wear-resistant components that are used to protect the rotor and crushing chamber from wear and tear.

The upper wear plate is typically located above the rotor and is designed to protect the top of the rotor and the crusher’s feed tube from wear caused by the material being crushed. The upper wear plate is usually made of high-chrome steel, which is a durable material that can withstand the high-impact forces generated by the crusher.

The lower wear plate, on the other hand, is typically located below the rotor and is designed to protect the bottom of the rotor and the crushing chamber from wear caused by the material being crushed. The lower wear plate is also made of high-chrome steel and is designed to be easily replaced when it becomes worn.

Overall, the upper and lower wear plates play an important role in the operation of a VSI crusher by protecting the rotor and crushing chamber from wear and tear, thereby ensuring that the crusher remains efficient and effective over time.

Replace upper and lower wear plates

Replace upper and lower wear plates when it is obvious that they will not last another shift. Replace once there is less than 3-5 mm of plate remaining at the center of the wear path at the discharge edge or inside edge.

Upper wear plates

Rapid upper wear plate wear is an indication that the feed tube and feed eye ring are worn. Replace worn parts. Upper wear plate wear accompanied by rotor tip-top end wear is an indication that the trail plates are incorrectly shaped.

Lower wear plates

Lower wear plate wear accompanied by rotor tip bottom end wear is an indication that the trail plates are incorrectly shaped.

Upper & lower wear plates removal

It is possible to remove and install the upper and lower wear plates while the rotor is in place, however, it is necessary to clean out the build-up thoroughly.

Upper wear plates removal

- Remove the roof and hopper in one lift. The hopper may be removed from the roof first if the lifting equipment being used does not have sufficient capacity to lift both assemblies together. When removing hopper assembly, remove clevis pin from the hydraulic ram and slide the control gate back as far as possible before lifting the hopper assembly.

- Remove rotor tips and tip carrier wear plates.

- Remove feed eye ring.

- Tap the wear plate towards the centre of the rotor to release it from the keepers.

- Withdraw the plate through the feed hole.

- Thoroughly scrub out the remaining build-up with a wire brush or hose pipe.

Lower wear plates removal

- Remove rotor tips and tip/cavity wear plates.

- Remove the distributor plate.

- Tap the wear plate towards the centre of the rotor to release it from the keepers.

- Withdraw the plate through the feed hole.

- Thoroughly scrub out the remaining build-up with a wire brush or hose pipe.

Wear plates Installation

- Ensure mating surfaces are clean and free of snags.

- Insert new wear plate through the feed opening and slide into place.

- Ensure the new plates are wedged under the keepers.

Download Brochure

Download Brochure Product List

Product List