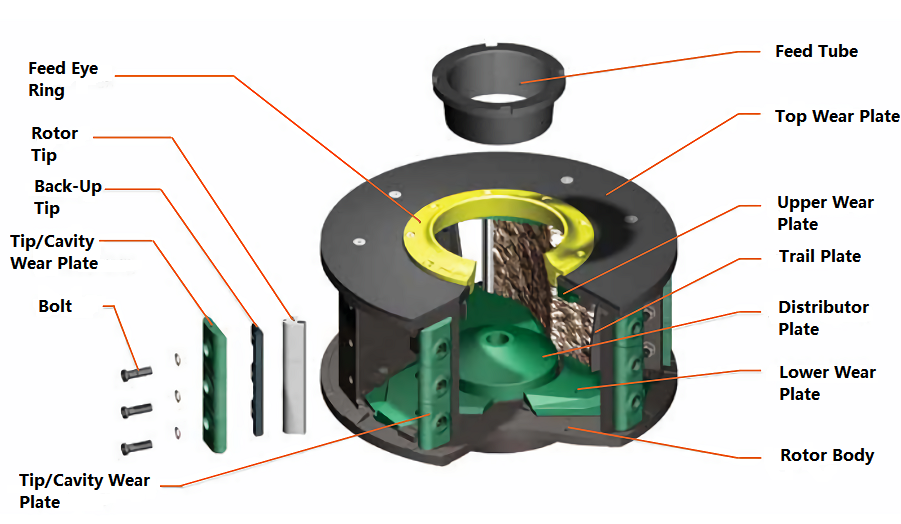

Here are the key parts of a VSI crusher and their functions:

- Distributor Plate

- Rotor Tips

- Upper and Lower Wear Plates

- Back-up Tips

- Tip / Cavity Wear Plates

- Trail Plates

- Feed Tube

- Feed Eye Ring

- Top and Bottom Wear Plates

Here are the key parts of a VSI crusher and their functions:

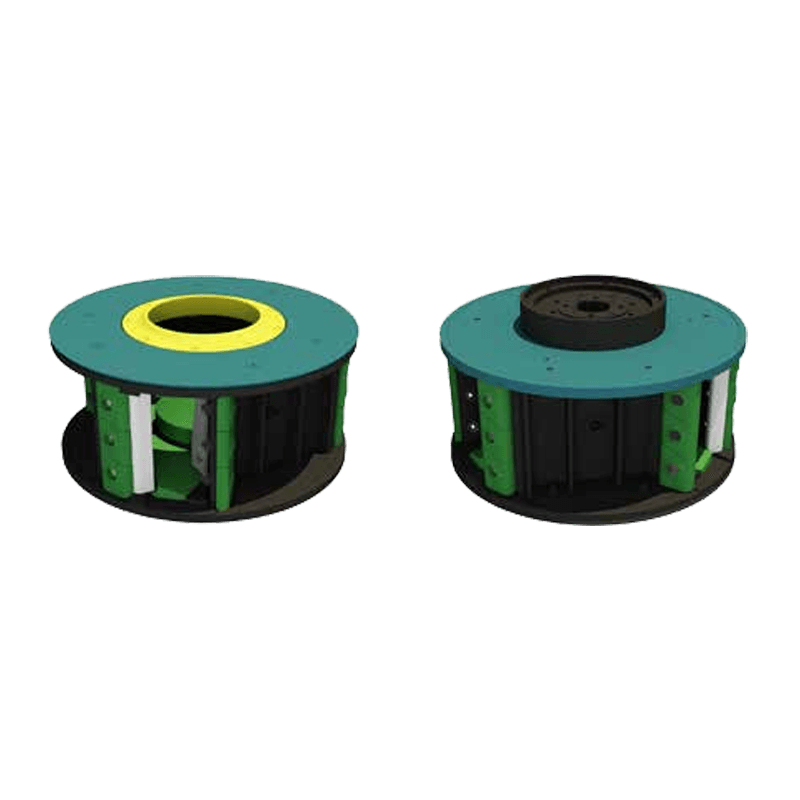

This is located above the rotor and helps to distribute the material evenly across the crushing chamber. The distributor plate is the wear part that receives the most impact wear(material feeding), and will normally wear out the fastest in standard applications. There is only 1 distributor plate in each dressed rotor.

The Feed tube is subject to high abrasive wear as all of the feed material going through the rotor will pass through it. The Feed tube is secured into the Spider assembly of the crusher using a clamp plate and spring handle.

The Rotor tips are the last thing to touch the feed material as it exits the rotor. They can have a Tungsten insert that improves wear life. We often use the life of the tips as a reference point for the other rotor wear parts.

The back-up tip is designed to protect the rotor if and when a rotor tip gets broken or worn out. When this happens the Tungsten insert in the rotor tip has split and is now letting feed material run against the Tungsten insert of the back-up tip.

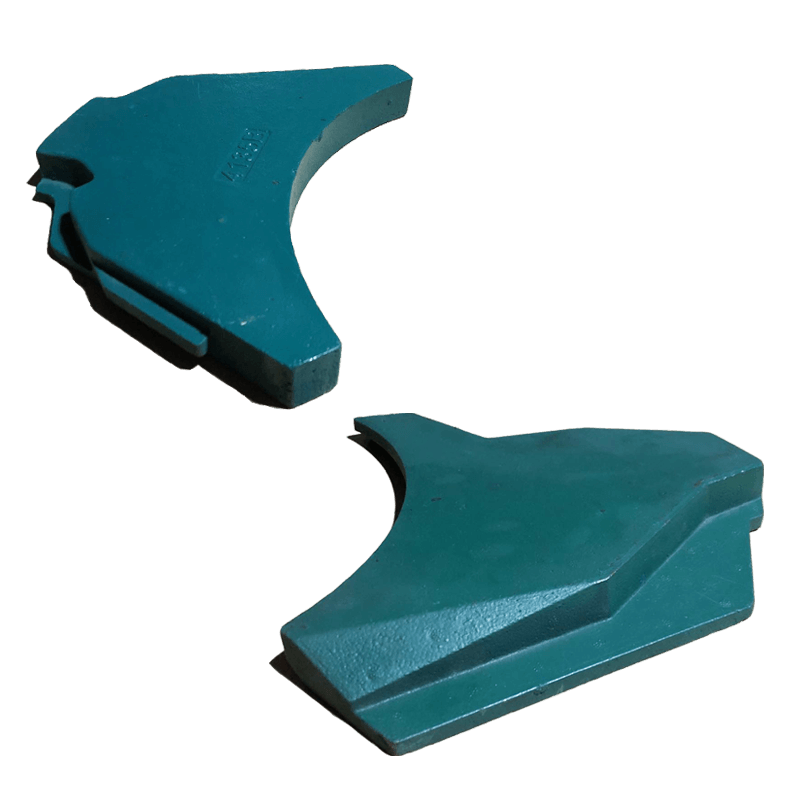

Tip / Cavity Wear plates are designed to protect the outside edges of the rotor against excited particles in the crushing chamber. As the rotor spins, it impacts particles that have rebounded from the chamber build-up after their initial exit from the rotor.

The Feed eye ring is subject to minimal wear in normal operating conditions, and in some rotors can be turned 3 times to maximise wear life. The Feed eye ring is secured to the feed opening of the rotor either with bolts or by dropping into slots and rotating to lock.

The Top and Bottom wear plate is designed to protect the top and bottom outside surfaces of the rotor. The top surface can get worn when the feed tube and feed eye ring are worn letting material though the gap created in the rotor feed opening. The bottom surface can get worn when material build-up in the crusher base becomes excessive and starts pushing upwards against the rotor.

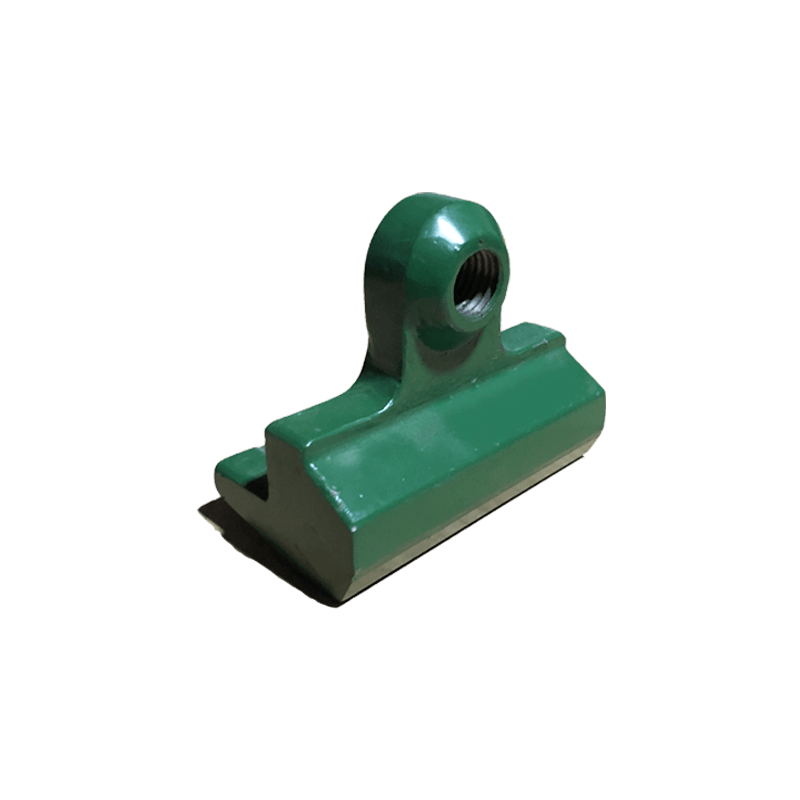

The Trail plates are designed to hold in the material build-up inside the rotor behind the rotor tips. They can be the least expensive wear part in a rotor, but as they are responsible for keeping the build-up in place, they are very important.

These wear plates are designed to protect the upper and lower faces of the inside of the rotor from the feed material as it passes through the rotor (the material build-up protects the sides).

When it comes to VSI crusher parts, Qiming Casting manufactures crusher wear parts for popular brand VSI crushers, including rotor tips, back-up set, distributor plate, feed tube, tip wear plates, and cavity wear plates. As a rich experience foundry, Qiming Casting has new designs for those VSI crushers, which are better quality than OEM replacement parts.

On the other hand, Qiming Casting is a superstock for popular brands VSI crushers. All Qiming Casting VSI replacement parts are backed by the ISO9001:2015 quality control system and are shipped only after meeting our rigorous quality standards. We are committed to meeting your replacement parts needs in a professional and efficient manner. Our Customer Support Department is ready to help you with a quote, to check inventory, or simply answer a technical question. Talk to your Qiming Casting professional today about your specific needs!