Manganese Steel Casting Foundry-Qiming Casting®

Qiming Casting is one of the largest manganese steel casting foundries in the China market, which focuses on casting Hadfield steel for crusher liners, mill liners, shredder wear liners, and apron feeder flights. Currently, our company is capable of designing, engineering, and manufacturing castings ranging anywhere from 5 kgs to 18000 kgs in weight.

Not only standard Hadfield steel (Mn14), Qiming Casting also cast super manganese steel (Mn18, Mn22) and manganese alloy steel (Mn14Cr2, Mn18Cr2, Mn22Cr2, Mn18Cr2NiMo, and other alloys) for mining, cement, and quarrying industry.

Qiming Casting serves a global base of original equipment manufacturers, metallic mines, and aggregate plants. We have developed a world-class facility to efficiently produce the highest quality manganese steel castings in a safe, quality-controlled, and environmentally sound manner.

Benefits

- Qiming Casting has two sand production lines, one V-method production line, and one lost foam production line. On the other hand, Qiming Casting has two 5 tons of electric furnaces, two 3 tons of intermediate frequency electric furnaces, and two 1 ton of intermediate frequency electric furnaces. Qiming Casting can produce up to 18,000 kg castings!

- We have over 20,000 original designs (CAD) and have OEM for some popular brands.

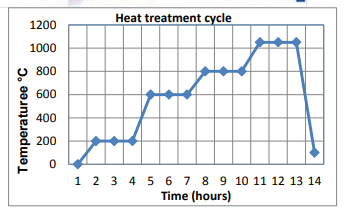

- A 30% reduction in our heat times has greatly increased capacity and efficiency.

- All our products are delivered ready to use.

- Our products are produced in a safe, quality-controlled environment.

- Our manganese steel casting production capacity: 15,000 tons per year.

Download Brochure

Download Brochure Product List

Product List