TIC Inlay Wear Parts

The crusher wear parts used in crusher lines represent a key factor in plant efficiency. With the development of the market for crushing, crushing has evolved. When crushing some super-hard stones, the traditional high manganese steel liners do not achieve good results and have a very short service life, and the replacement cycle of the liners is also very short.

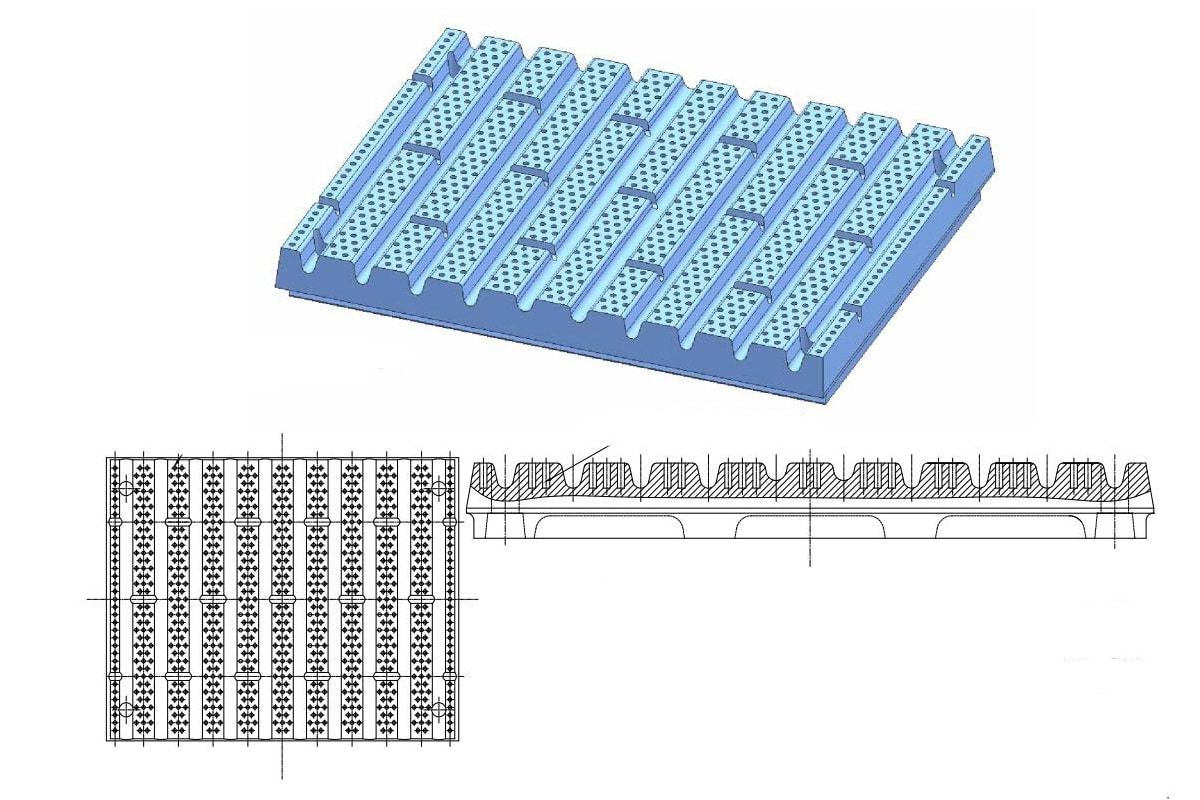

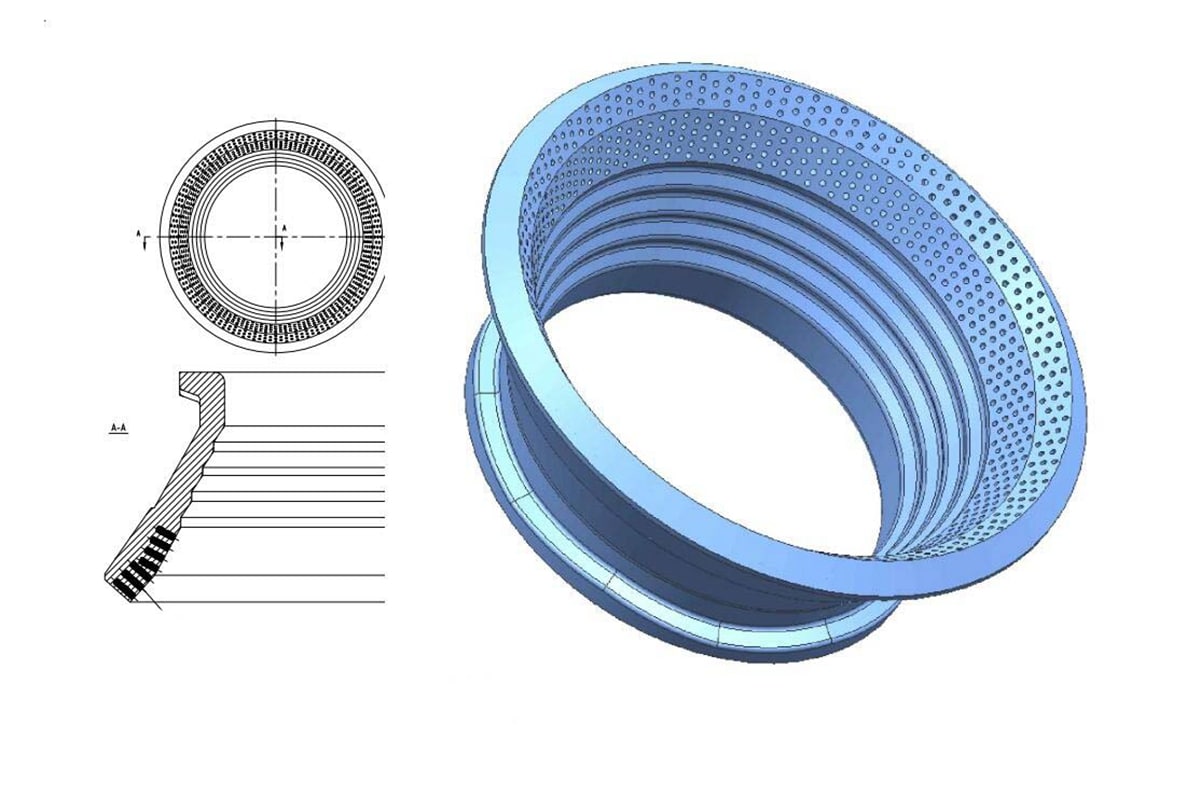

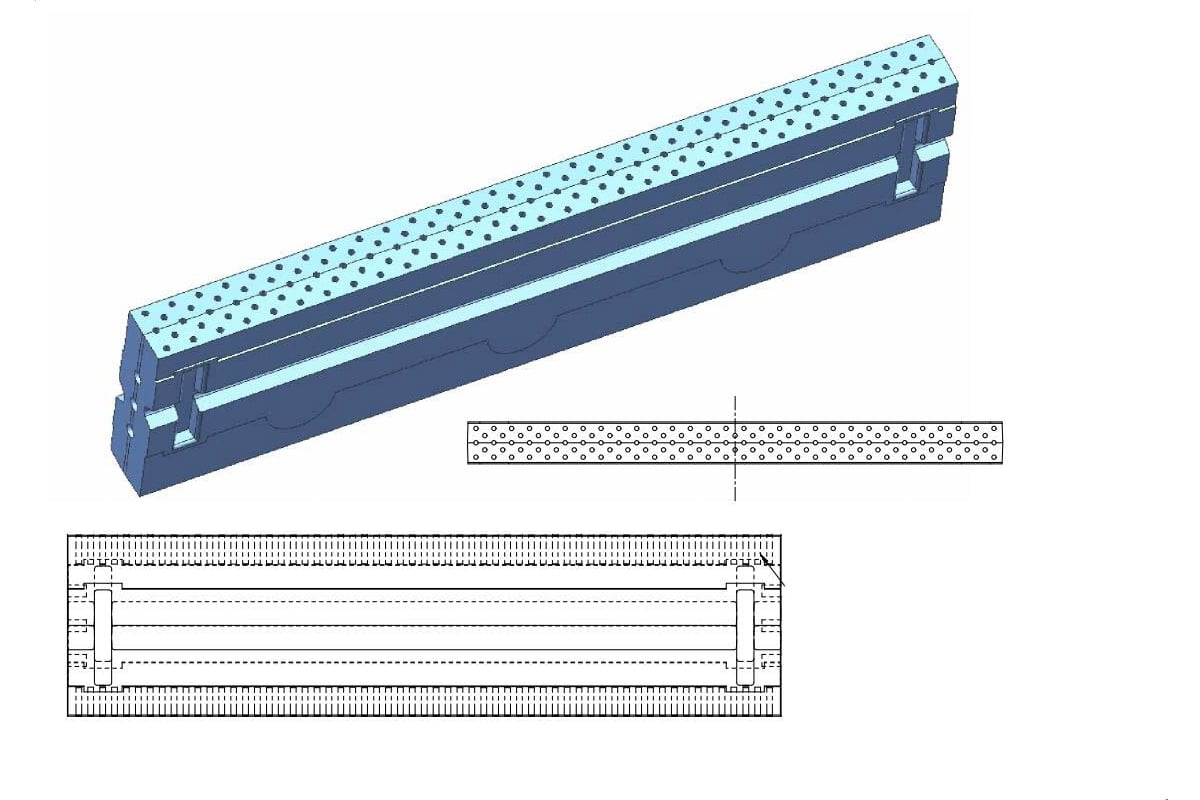

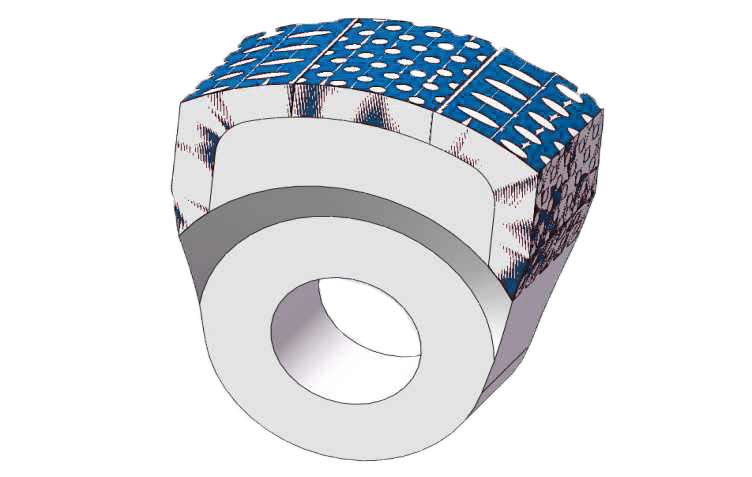

To solve this challenge, Qiming Casting’s engineers have developed a new crusher liner series, TIC Inlay Wear Parts, with the goal of extending the lifetime of these tools. Featuring a special alloy, the high-quality TIC inlay wear parts from the Qiming Casting ensure substantially enhanced economic efficiency and can be used in all types of crusher series.

Working principle

Our engineers inlay the titanium carbide rods on the working surface of the liner. When the stone enters the crushing chamber, it first comes into contact with the raised titanium carbide rods, which wear very slowly due to their ultra-hardness and wear resistance. At the same time, due to the protective effect of the titanium carbide rods, the matrix of the high manganese steel also slowly comes into contact with the stone and the matrix slowly hardens.

Download Brochure

Download Brochure Product List

Product List