Qiming Casting-China’s Wear-resistant Casting Industry Leader

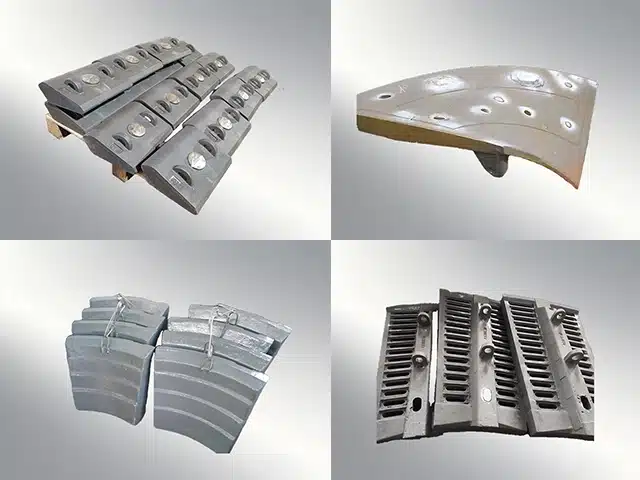

Qiming Casting is a Chinese foundry that produces wear-resistant materials for the mining, quarrying, cement, coal, and metal recycling sectors.

Established in 2010

- Modified water glass process with a designed production capacity of 10000 tons and a maximum single weight of 15 tons.

- Focusing on researching how to improve the comprehensive performance of high manganese, chrome, and alloy steel.

- Help customers improve product design based on materials and working conditions, increase production, and save resources.

- According to the actual needs of customers, we continue to develop new materials that are more wear-resistant.

Download Brochure

Download Brochure Product List

Product List