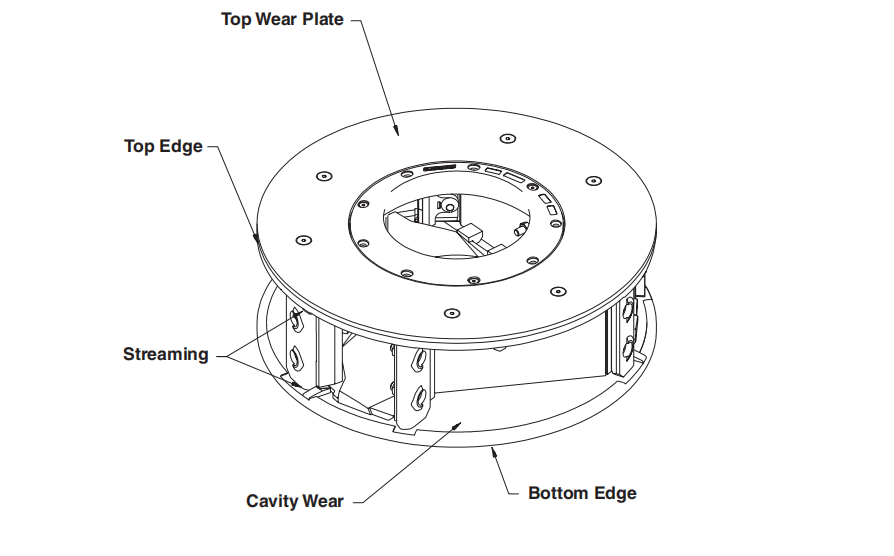

VSI Crusher Rotor Body Wear Problems

This paper shows the subject to normal wear – the comments provide a guide to causes of unusually rapid wear- for the VSI crusher rotor body.

Top Wear Plate Wear

The feed tube is too short and material discharges over the rotor’s top. Replace the feed tube or remove dust build-up. If the top wear plate continues to wear it may be necessary to replace the mild steel top wear plate with a more wear-resistant material. Don’t hesitate to get in touch with your plant representative.

Top Wear Plate Wear

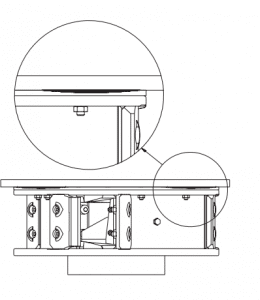

Top Edge Worn

Wear skirt and/or cavity ring is worn. Replace worn parts.

Top Edge Worn

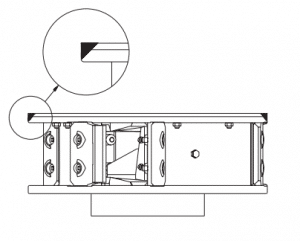

Streaming Wear

This is more prevalent in wet and/or very abrasive fine applications and is caused by dust streamlining around the tip/cavity wear plate. Effects can be reduced by sealing the gap between the top and bottom edges of the tip/cavity wear plate and the rotor with a silicone rubber or urethane sealant.

If the rotor has been in service for some time it is important to check possible wear on the back-up tip holder. If the protrusions have worn, streaming wear will be more prevalent.

Streaming Wear

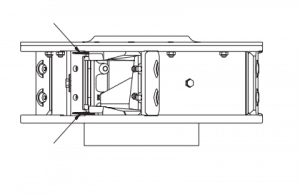

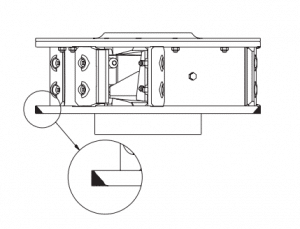

Bottom Edge Worn

Can be a feature of high tonnage operation or indicative of excessive build-up in the base that is rubbing on the rotor. Reduce build-up by reducing moisture content of feed or introducing water spray system.

Bottom Edge Worn

Download Brochure

Download Brochure Product List

Product List