Mn18Cr2 Crusher Liners Casting Standard For Qiming Casting

This article is about Qiming Casting’ Mn18Cr2 crusher liners casting standard. Those crusher liners are included: cone crusher mantle, cone crusher concave, fixed jaw plate, movable jaw plate, and cheek plates.

This material is similar to Metso XT710 material and Sandvik 002 material.

Applied Standard (Production Casting)

- Visual examination of surface quality of steel castings (ISO adoption of SCRATA and BNIF) —— ISO 11791

- Comparators for the Definition of Surface Quality of Steel Castings (Shorter Set in Accordance with ASTM A 802)——-SCRATA Handbook

- Characterization of Surface Conditions of Castings——BNIF 359-01

Technical Requirements

Material Requirements

Chemical analysis (ladle analysis) ranges (% min./max.) shall be as follows:

| C | Mn | Cr | Si | P | Fe |

| 1.15 | 17.00 | 1.75 | 0.40 | — | Balance |

| 1.35 | 18.5 | 2.5 | 0.9 | 0.055 | Balance |

Casting hardness (indicative initial hardness) shall be within the range of 200-250 HB.

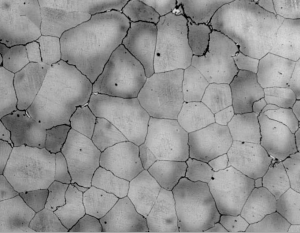

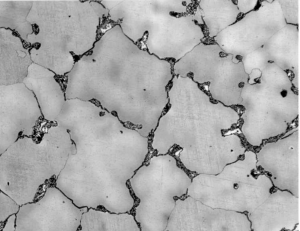

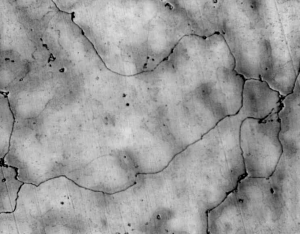

Carbides are not allowed at grain boundaries. Acceptance criteria is per attached microstructure photographs (magnification 100x):

- A: Acceptable

- B: carbides at grain boundaries – not acceptable

- C: coarse grain structure – not acceptable

Non-Destructive Testing

Visual acceptance criteria shall be per SCRATA as follows:

- Wear surface: A3/A4, C4, E5, G3, J2

- Other surfaces: A5, C4, E5, G3, J4

Cracks are not allowed.

Check all castings to their drawings, and to Technical Data TD4-003 where applicable.

Welding Repairs

Qiming Casting shall submit its welding repair procedure to the purchaser for approval. The procedure shall include all necessary welding parameters. The welding electrode must be compatible with austenitic manganese alloy.

The size of the weld repairs is limited. The maximum size of excavations shall be:

- 10 x 10 x 10 mm ( .4 x .4 x .4 in.) (on the wear surface)

- 80 x 80 mm (3.2 x 3.2 in.) (on all other surfaces, with a depth of 25 mm (1 in.) or 25% of the wall thickness, whichever is smaller).

For larger repairs, Qiming Casting shall submit a written request to the purchaser for approval to repair. In this case, the entire casting must be fully re-heat-treated.

Casting defects shall be excavated by grinding or arc-air gouging. If the excavation is done by arc-air gouging, the excavation shall be ground. The excavation shall be inspected visually to ensure that the defect is completely removed.

Documentation

Serial casting documentation shall include:

- Chemical analysis of every melting charge.

- Heat treatment records including temperature graph.

- Declaration that castings meet all quality requirements stated in this specification and purchase orders.

- Pilot casting/first article documentation shall also include radiography records and microstructure photographs at 100x scale.

Additional Pilot Casting Applied Standards

- Standard Reference Radiographs for Heavy-Walled (2 to 4-1/2 in. (51 to 114 mm)) Steel Castings — ASTM E 186

- Standard Reference Radiographs for Heavy-Walled (4-1/2 in. to 12 in. (114 to 305 mm)) Steel Castings — ASTM E 280

- Standard Reference Radiographs for Steel Casting up to 2 in. (51 mm) in Thickness — ASTM E 446

Pilot Casting Requirements

Casting internal soundness shall be proven on pilot castings per the applied standards listed in the last paragraph. Internal soundness shall be at the agreed level for each application.

On all pilot castings, whether new or when patterns are modified significantly, Qiming Casting shall perform the following procedures:

- Provide evidence of chemical and mechanical conformance to this specification.

- Provide evidence of radiographic testing conformance to applicable ASTM E 446, E 280 or E 186 acceptance levels upon request and/or agreement.

- Provide a layout report (a print of the casting drawing with actual measurements written in next to all drawing dimensions and specifications is acceptable), plus casting method including dimensions for gates and risers, as well utilities used in method plan.

- Provide evidence that internal discontinuities in the crushing zones of pilot castings do not exceed level 3 for gas porosity (defect A) and all 3 types of shrinkages (defect C). Sand and slag inclusions (defect B), cracks (defect D), hot tears (defect E) and inserts (defect F) are not permitted.

Pilot Casting Requirements (PHOTOMICROGRAPHS)

Carbides are not allowed at grain boundaries. Acceptance criteria are per the microstructure photographs on pages 5 and 6 of this standard (100x scale):

- A: acceptable

- B: carbides at grain boundaries – not acceptable

- C: coarse grain structure – not acceptable

Download Brochure

Download Brochure Product List

Product List