Cone Crusher Sheave

What is cone crusher sheave?

A cone crusher sheave is essentially a pulley or a wheel that helps to transmit power from the motor to the cone crusher’s main shaft. The sheave is typically made of cast steel and is designed to transfer rotational motion from the motor to the eccentric shaft that rotates the mantle of the cone crusher.

The cone crusher sheave is typically mounted on the motor shaft or on a countershaft that is connected to the motor through a belt or chain drive. The sheave is usually a solid disk with a grooved circumference that matches the shape of the drive belt or chain. The grooves help to grip the belt or chain and prevent slipping, which is important for ensuring efficient power transmission.

The cone crusher sheave is an important component of the cone crusher, as it helps to transfer power and rotational motion from the motor to the mantle, which is responsible for crushing rocks and other materials. The size and shape of the sheave can vary depending on the size and type of cone crusher, as well as other factors such as the power output of the motor and the speed of rotation.

How to install the crusher sheave?

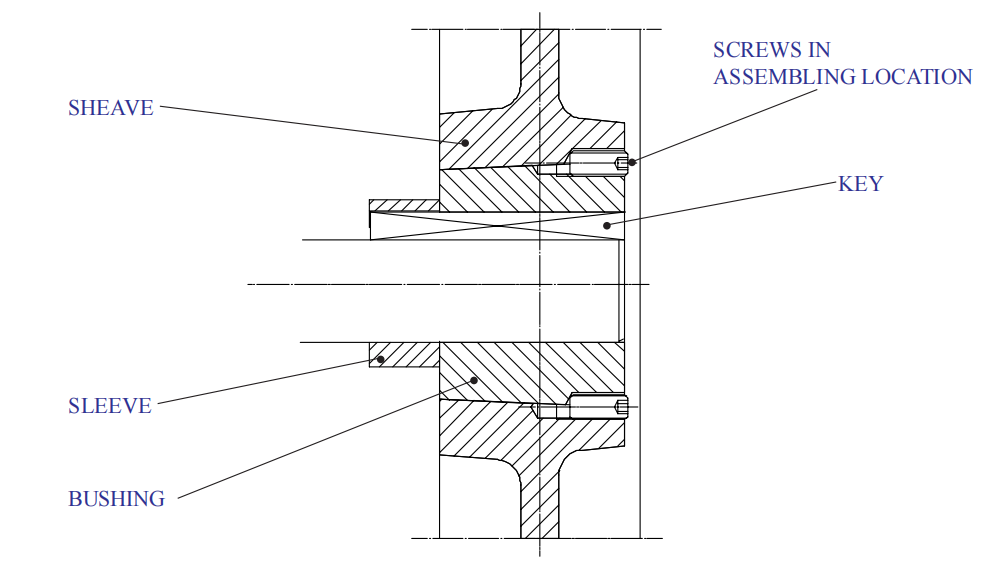

To install a crusher sheave with a removable bushing, proceed as follows:

- Refer to the oil piping drawing and install all oil piping.

- Remove the removable pulley hub by removing the tightening and loosening screws.

- Clean the shaft, the key, the surfaces, and the outer cone of the hub together with the conical bore of the pulley on which it is to be assembled. Remove chips and varnish and paint marks.

- Pull the countershaft to the outside of the crusher so that the pinion is bearing on the countershaft box bushing. Check the axial clearance of the countershaft.

- Place the sleeve and the removable hub in the conical pulley bore, ensuring the smooth half holes are placed opposite the tapped half holes.

- Oil the thread and the rounded end of the screws (or underneath the head for screws with the head).

- Place the screws in the tap holes on the pulley without tightening them. The hub is free on the rim.

- Slide the assembly onto the shaft until the required position is reached. Do not forget the key (keyed pulley version).

- Evenly tighten the screws in turn. They should be tightened until they are locked at the required torque.

How to remove the crusher sheave?

To dismantle the crusher sheave, proceed as follows :

- Firstly remove the hub fastening screws.

- Insert the screws into the hub tap holes.

Should it prove difficult to separate the pulley from its removable hub, strike it gently with a hammer while maintaining pressure on the thrust screws.

Download Brochure

Download Brochure Product List

Product List