Our customer operates a stone quarry in Serbia. They use the GM Impact Crusher produced in Turkey. After running for a while, the customer found that the accompanying blow bar was not very wear-resistant, so they replaced it with a blow bar produced in the Serbian factory. The result was still the same. Not wear-resistant.

After communicating the working conditions in detail, we designed TIC insert blow bars for him.

Background

Machine: General 800 Mobile Crusher

Working conditions:

- Crushed material: Limestone

- Input size: ≥800 mm

Used blow bars: Mn18Cr2 blow bars

Challenges

Customer feedback: Whether it is the blow bars produced in Türkiye or Serbia, the span life is not good, just around 15 days per side. The service life is short, the replacement cycle is fast, which affects production capacity, and the replacement cost is high.

Solution

Qiming Casting designs new material blow bars for him. (TIC+Mn18Cr2MoNi)

Customer Feedback & Results

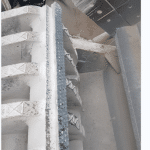

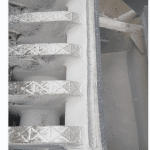

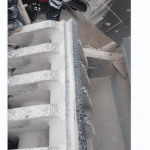

After our product ran for 15 days, the customer conducted regular inspections and maintenance:

TIC Inserts Blow Bars Feedback after 15 days (1)

TIC Inserts Blow Bars Feedback after 15 days (2)

TIC Inserts Blow Bars Feedback after 15 days (3)

- Normal wear

- No drop out

- Work well

60 days later, the Customer gave us feedback: “TIC blow bars for GM met expectations, two months one side, that’s about 70-80% more than previously used.”

TIC Inserts Blow Bars Feedback from Serbia (1)

TIC Inserts Blow Bars Feedback from Serbia (2)

TIC Inserts Blow Bars Feedback from Serbia (3)

TIC Inserts Blow Bars Feedback from Serbia (4)

Summary

Qiming Casting’s TIC inserts for GM blow bars are proven to have a lifespan 70-80% longer than Mn18Cr2 blow bars. This means they can operate for over four months, making them a superior choice for your needs.

Download Brochure

Download Brochure Product List

Product List