Cone Crusher Liners Selection

Cone crusher ,which is the most popular crusher type in the world than jaw crusher and impact crusher. Cone crusher liners , the mainly wear parts in cone crusher, and also need exchange them very regularly.In this post, we will analysis the selection by cone crusher cavity,crusher liner’s material and exchange time. We will choose cone crusher toanalysis.

1. Cone Crusher Cavity

Cone crushers have three series types, MP series cone crusher (MP800,MP1000,MP1250), HP series cone crusher (HP100,HP200,HP300,HP400,HP500,HP800),GP series cone crusher(GP100,GP200,GP300S,GP300,GP11F,GP220….)

2. Crusher Liner’s Material

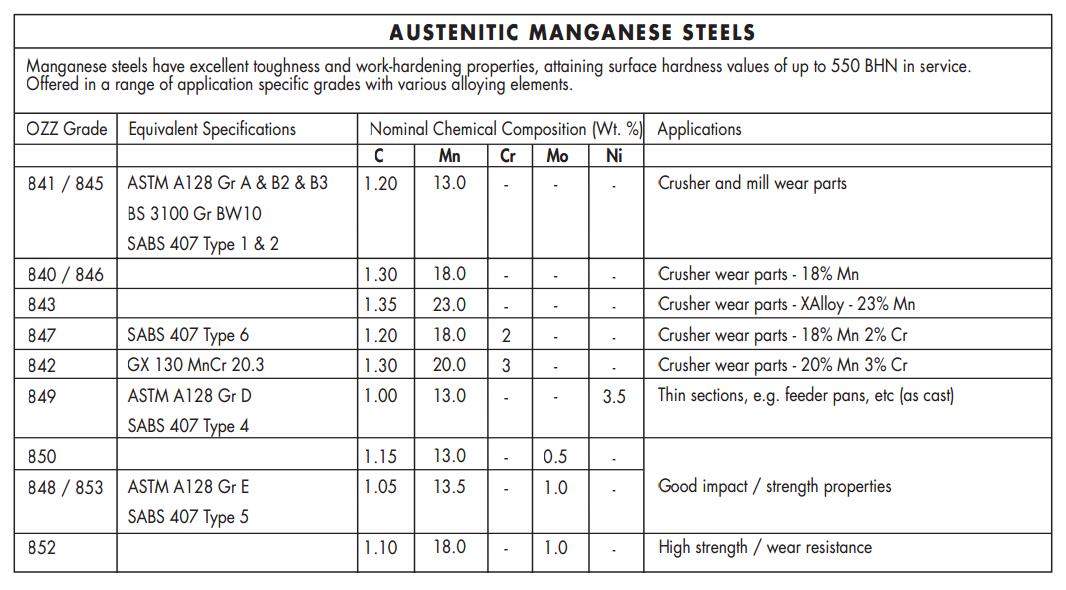

Cone crusher wear parts, concave and mantle, are casting by manganese steel. Mangalloy, also called manganese steel or Hadfield steel, is a steel alloy containing an average of around 13%manganese. Mangalloy is known for its high impact strength and resistance to abrasion once in its work-hardened state. (From Wikipedia.com)

3. When to change the old crusher liners?

In order to avoid damage to the liner seating surfaces of the crusher head or bowl, wear parts must be replaced before they are worn through. In normal conditions, approximately 50% of the liner weight is consumed when liners are worn out. It is important to keep a record of liner wear in order to assess the degree of liner wear without the need to stop the crusher operation.

In fact, the exchange time based on the rate of cost and profit. In our experience, the quantity of output will decrease with abrasion of concave and mantle.

For example:

Production rate: 200 tons per hour of products,and Crush profit $5.0 per ton hours per day with 10 production hours per day.

If there is a 10% reduction in production results, you will lost $1000 per day in gross profit.A news set liners maybe just need $3000,when do you want to exchange new crusher liners? You can calculate it!

Download Brochure

Download Brochure Product List

Product List