Introduction

In the demanding world of aggregate processing, wear part selection dramatically impacts your operational efficiency and profitability. When a Romanian quarry faced the challenge of maintaining their Magotteaux 2100 VSI crusher while controlling costs, they turned to Qiming Casting for a solution. The results: Significant savings without compromising performance.

This case study explores how strategic material selection can deliver outstanding value—even when compared to premium OEM parts. Read on to discover how our wear parts performed in real-world conditions and why more operations are choosing Qiming Casting for their critical wear components.

The Solution: Strategic Material Selection and Precision Manufacturing

Understanding VSI Wear Components

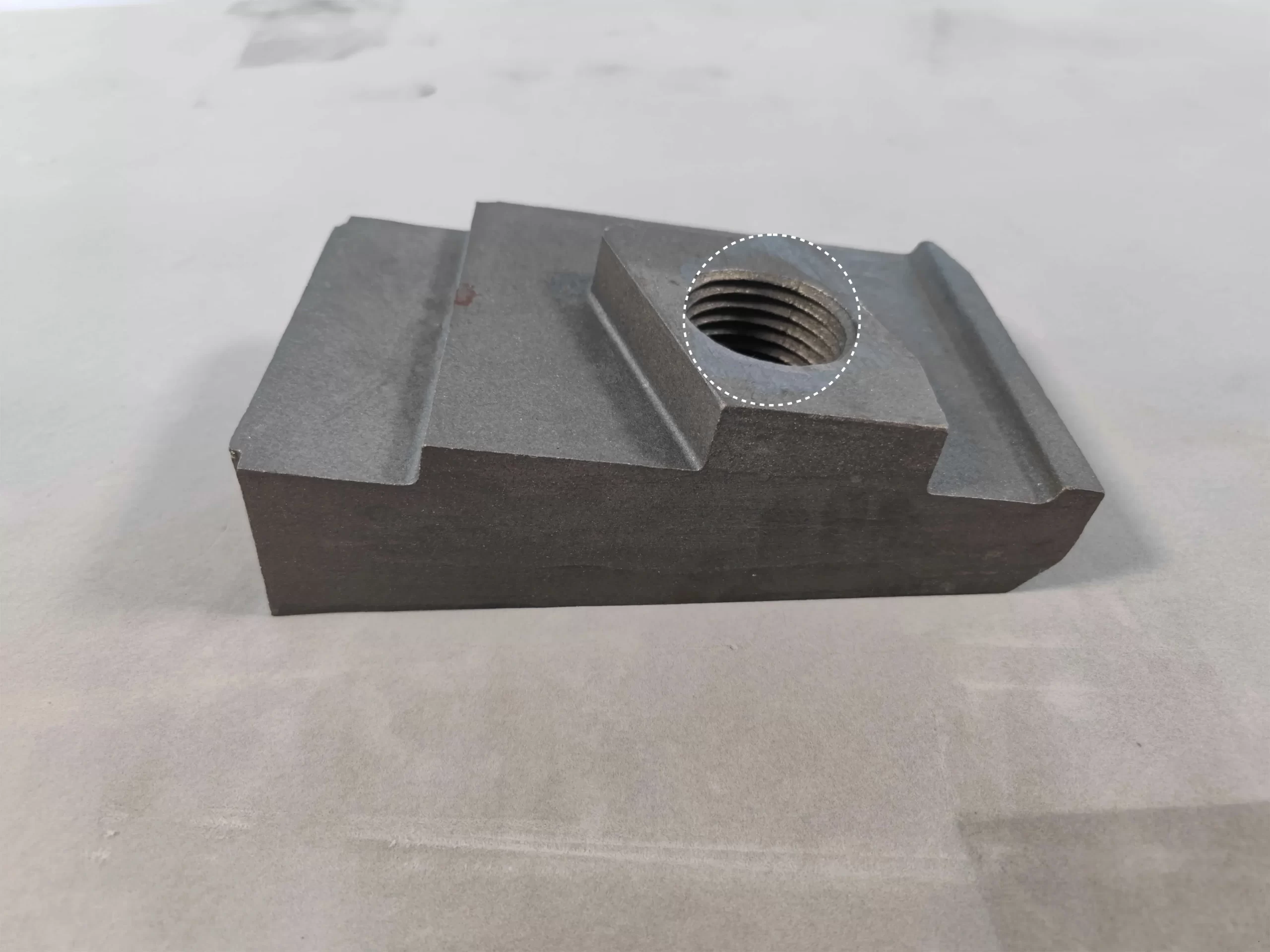

VSI crushers operate on the principle of high-velocity impact crushing, where rock particles are accelerated and thrown against wear-resistant surfaces . The VSI shoes (also called impeller shoes) and VSI anvils (impact plates) bear the brunt of this abrasive action, making their material composition critical to performance and longevity.

Qiming Casting’s Two-Pronged Approach

We proposed testing two different material formulations against the OEM benchmark:

-

Standard High-Chromium Iron (Hi-Cr) Parts

-

Traditional high-chromium cast iron composition

-

Industry-standard wear resistance

-

Priced at approximately 40% of OEM costs

-

-

Advanced Chrome-Ceramic Composite Parts

-

High-chromium iron base with integrated ceramic components

-

Similar to the OEM’s chrome-ceramic material technology

-

Priced at approximately 70% of OEM costs

-

The Results: Quantifiable Performance and Economic Analysis

In September 2025, after several months of rigorous operation, the Romanian quarry provided detailed performance data:

Service Life Comparison

| Wear Part Type | Service Life (Hours) | Relative to OEM (%) | Cost Relative to OEM (%) |

|---|---|---|---|

| OEM (Magotteaux) | 50 hours | 100% | 100% |

| Qiming Standard Hi-Cr | 25 hours | 50% | 40% |

| Qiming Chrome-Ceramic | 46 hours | 92% | 70% |

Economic Value Analysis

While the standard high-chromium parts provided approximately half the service life of OEM components, their significantly lower cost (40% of OEM price) created an interesting value proposition:

Standard High-Chromium Parts Value Calculation:

-

Cost per operating hour = 0.4/25 = 0.016 (OEM equivalent units)

-

56% better value per hour compared to OEM parts

Chrome-Ceramic Composite Parts Value Calculation:

-

Cost per operating hour = 0.7/46 = 0.0152 (OEM equivalent units)

-

Approximately 60% better value per hour compared to OEM parts

Both Qiming Casting options delivered superior economic value compared to the OEM parts, with the chrome-ceramic composite providing nearly identical performance at a significantly lower operating cost.

Conclusion: Making Informed Decisions for Your Operation

The Romanian quarry case study demonstrates that informed material selection can significantly impact your bottom line. While OEM parts provide benchmark performance, aftermarket alternatives from quality-focused manufacturers like Qiming Casting can deliver superior economic value without sacrificing performance.

For operations using Magotteaux 2100 VSI crushers—or similar equipment—the choice between standard high-chromium and advanced chrome-ceramic components depends on your specific priorities:

-

Choose standard high-chromium parts when initial cost is the primary concern and you can accommodate more frequent changes

-

Select chrome-ceramic composites when you seek near-OEM performance with significantly better economics

-

Consider a mixed approach using premium components in high-wear areas and standard parts in less critical positions

As the aggregate industry continues to face pressure to reduce costs while maintaining productivity, strategic decisions about wear parts become increasingly important. With Qiming Casting as your partner, you can optimize this critical aspect of your operation with confidence.

Ready to optimize your wear part strategy? Contact our technical team today for a personalized analysis of your specific application and operational requirements.