In the demanding world of raw material processing, roll crusher tooth segments stand as critical components whose longevity directly impacts operational efficiency and profitability. Traditional materials like Mn14Cr2 and Mn18Cr2 have long been the industry standard; however, they often necessitate disruptive maintenance cycles and replacement costs. Qiming Casting’s engineering breakthrough—featuring strategically embedded titanium carbide (TiC) rods within an optimized Mn18Cr2 matrix—has redefined durability benchmarks. In rigorous Russian coal grinding trials, this innovative solution delivered an unprecedented 39 days of continuous service, outperforming conventional alternatives by a remarkable 85% increase in lifespan.

BACKGROUND

In the harsh and remote mining regions of Russia’s Far East, operational efficiency and equipment reliability are not just goals—they are necessities for survival. A major Russian coal producer faced a critical and persistent challenge with a key piece of their processing equipment: a roll crusher from a leading European brand, used for the primary reduction of raw coal ore.

The core of the problem lay in the crusher’s original tooth segments. Manufactured from a standard Mn14 material, these segments were failing at an alarming rate. Under the intense abrasion of the coal ore, a full set of segments would last only 14 days before becoming too worn to maintain product size specification or operational safety.

This 14-day lifecycle created a debilitating cycle for the operation:

-

Frequent Production Halt: Every two weeks, the entire crushing line had to be shut down to allow for the complete replacement of the segment plates.

-

Massive Downtime Costs: Each changeout consumed valuable hours of labor, during which the entire production process was stalled, leading to significant losses in output and revenue.

-

Spiraling Operational Expenses: The constant need for new replacement parts, combined with the high cost of emergency maintenance in a remote location, was making the crushing operation prohibitively expensive and unpredictable.

The client was trapped in a cycle of reactive maintenance. They were not operating the crusher; they were serving it. The short service life of the Mn14 segments was the bottleneck constraining their entire production capacity. The client urgently needed a fundamental change—a solution that would dramatically extend operational uptime, reduce maintenance frequency, and deliver a predictable, lower cost-per-ton crushed. They needed a partner who could solve the material science challenge at the heart of their problem.

CHALLENGES

The client presented a clear but demanding objective: extend the service life of the tooth segments to over 30 days—more than double the lifetime of the original Mn14 parts.

Achieving this goal was critical to transforming their operation. However, this single target introduced a complex set of engineering challenges:

-

Dramatic Wear Resistance Improvement: The new segments needed to withstand the highly abrasive coal ore for over 30 days without critical failure, requiring a fundamental leap in material science.

-

Uncompromised Performance: The solution must not sacrifice crusher performance. It had to maintain the required throughput (tons per hour) and ensure a consistent product size distribution.

-

Economic Justification: The longer lifespan had to translate into a clear reduction in total operating costs, justifying the investment by slashing downtime and labor expenses associated with frequent change-outs.

Simply put, the challenge was to develop a segment that was not only vastly more durable but also equally efficient and economically viable.

SOLUTION

Faced with the limitations of conventional materials, Qiming Casting engineered a revolutionary third solution that moved beyond alloy composition into advanced composite design.

-

First Iteration: Mn18Cr2

We initially replaced the standard Mn14 material with an upgraded Mn18Cr2 alloy. This formulation increased both manganese and chromium content, aiming to boost the segment’s initial surface hardness and overall wear resistance. The client reported a service life extension to 16 days, a slight improvement but far short of the 30-day target. -

Second Iteration: Mn18Cr6

Analysis indicated that hardness remained the limiting factor. In the next iteration, we significantly increased the chromium content by an additional 4%, producing an Mn18Cr6 alloy. This change delivered a more substantial performance gain, extending the operational life to 21 days. While this confirmed our direction, it proved that incremental improvements in standard alloy composition were insufficient to reach the client’s goal.

Faced with the diminishing returns of conventional metallurgy, a radical technological leap was required.

-

The Third & Final Iteration: TiC-Embedded Engineering

The client informed us that other foundries had tried ultra-high-hardness materials like Cr26 and 40CrNiMo, which achieved longer life but failed catastrophically due to fracture. Learning from this, we knew a solution must combine extreme hardness with superior toughness.Leveraging our proven expertise with TiC-Insert technology in jaws and cones, we proposed a paradigm-shifting solution: a composite segment with strategically embedded titanium carbide rods. After detailed analysis, the client approved a minor tooth profile modification to enable this advanced manufacturing. Our final approach had three key pillars:

-

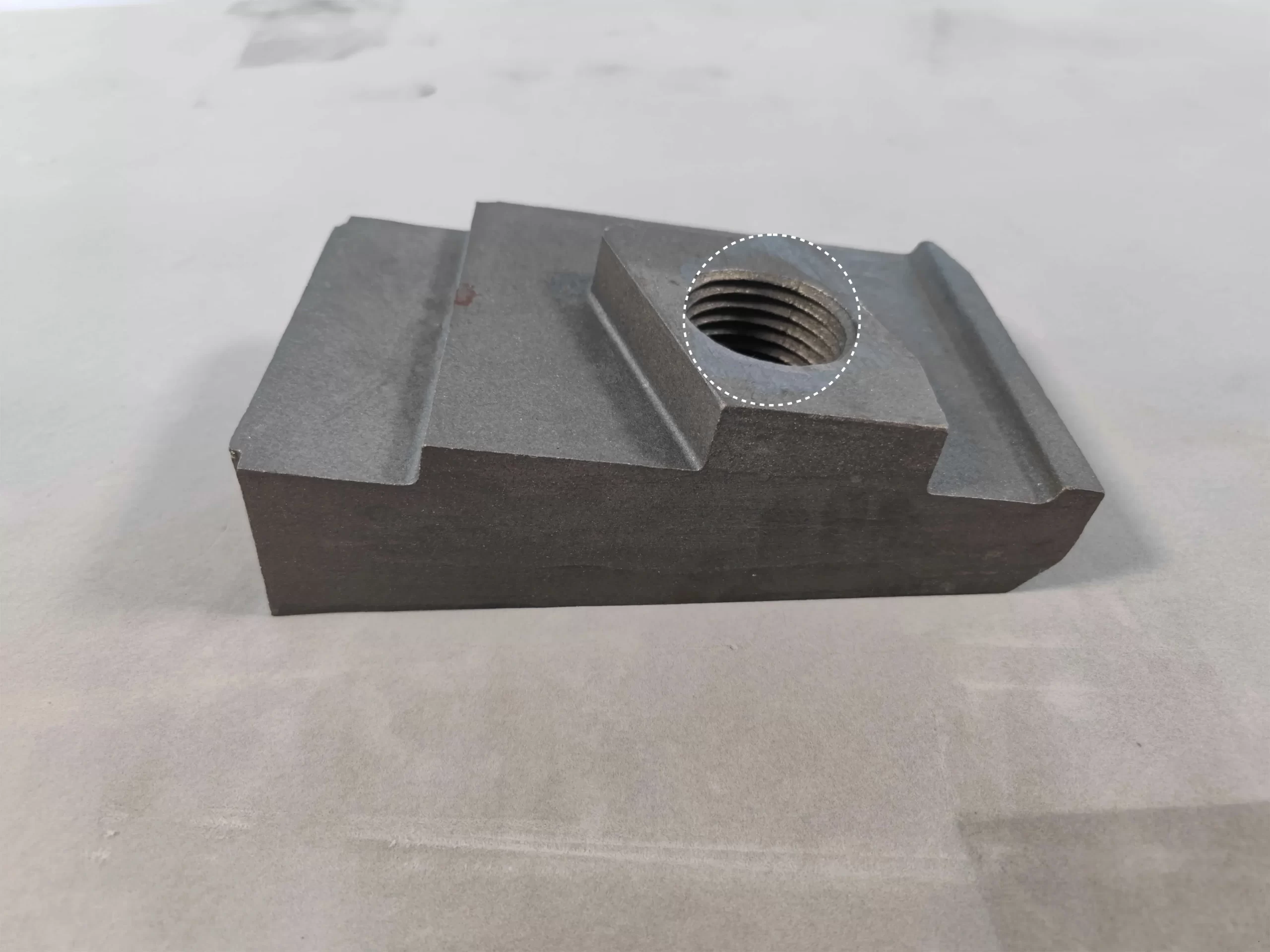

Optimized Tooth Profile: We changed the sharp tooth tip to a flat-top design. This provided a robust platform for TiC rod placement without altering the segments’ mounting dimensions or the crusher’s fundamental discharge settings, thus preserving final product size.

-

Strategic TiC Reinforcement: We embedded high-hardness Titanium Carbide (TiC) rods (Ø14mm x 60mm) directly into the core of each wear point. These rods act as a permanent, ultra-wear-resistant “skeleton,” bearing the brunt of the abrasive forces.

-

Enhanced Toughened Matrix: To prevent the brittle fracture seen in competitors’ solutions, we engineered a superior base material. We started with a Mn18Cr2 foundation and added Molybdenum and rare earth elements. This created a tougher, more resilient matrix that could firmly support the TiC rods and absorb high-impact loads without cracking.

This third solution was no longer a simple material replacement; it was an intelligently engineered Composite Wear System designed to master the balance between hardness and toughness.

-

PERFORMANCE & RESULTS

Following the implementation of our third-generation TiC-embedded solution, we awaited the results with great anticipation. The feedback from the client was nothing short of transformative.

After an extended period of rigorous operation in their Far Eastern coal processing plant, the data confirmed a resounding success: the Qiming Casting TiC-embedded segments achieved a groundbreaking service life of 39 days.

This exceptional performance delivered on every key objective:

-

Shattered Longevity Target: The 39-day lifespan surpassed the client’s 30-day goal by 30% and represented a 178% increase over the original Mn14 segments.

-

Zero Structural Failure: Critically, the segments exhibited no signs of fracture, cracking, or tooth breakage, a common failure point they had experienced with other suppliers’ high-hardness alloys. The engineered balance between the ultra-hard TiC rods and the toughened matrix proved flawless.

-

Uncompromised Output: Throughout the 39-day service period, the crusher maintained consistent throughput and produced the required product size, confirming that the minor tooth profile modification did not impact performance.

The operational and economic impact was immediate and profound. The dramatic reduction in replacement frequency and elimination of unplanned downtime delivered the significant cost savings the client desperately needed.

This unprecedented success directly translated into a powerful vote of confidence. Satisfied with the proven return on investment, the client placed a single, bulk order for 35 complete sets (totaling 1,680 pieces) of the revolutionary TiC-embedded segments, securing long-term operational stability and solidifying a strategic partnership with Qiming Casting.

SUMMARY

A Targeted Solution for Extreme Wear Problems

The remarkable success of our TiC-embedded segments in the Russian coal mine demonstrates the power of targeted material science. This case study highlights a critical principle at Qiming Casting: there is no universal “magic bullet” for every wear problem.

The Titanium Carbide (TiC) rod-embedded technology is a highly effective solution, but it is specifically engineered for certain severe, high-abrasion applications—like the coal processing in this case—where its superior properties can be fully utilized to deliver unparalleled service life.

However, it may not be the most cost-effective choice for all operating conditions. The true key to maximizing your operational efficiency and reducing Total Cost of Ownership (TCO) lies in selecting the right material for your specific application.

This is where Qiming Casting stands apart.

As a professional wear parts supplier, we offer more than just standard products; we provide customized technical service and expert guidance.

-

We analyze your specific material, equipment, and operational goals.

-

We help you navigate the material selection maze, from standard Mn14 to advanced Mn18Cr6, and up to revolutionary TiC-embedded composites.

-

We engineer the optimal solution that balances performance, lifespan, and cost for your unique situation.

Ready to Find Your Optimal Solution?

Don’t gamble on material selection. Let our engineering team conduct a thorough analysis of your wear challenges and recommend the most effective and economical path forward.

[Contact Qiming Casting for a Professional Wear Parts Consultation] – Together, we can engineer a solution that truly fits your operation.