Thailand’s largest cement producer faced significant operational challenges with their primary impact crusher blow bars, requiring replacement every 30 weeks and causing substantial production downtime. Qiming Casting engineered a revolutionary TIC-embedded solution that extended service life to 65 weeks – a 117% improvement – while dramatically reducing maintenance frequency and operational costs.

Background: The High Cost of Frequent Blow Bar Replacement

The client operates one of Southeast Asia’s most advanced cement production facilities, where reliability and operational efficiency are paramount. Their primary impact crusher processes massive volumes of raw materials, making blow bar performance critical to overall production throughput.

The challenge was substantial:

-

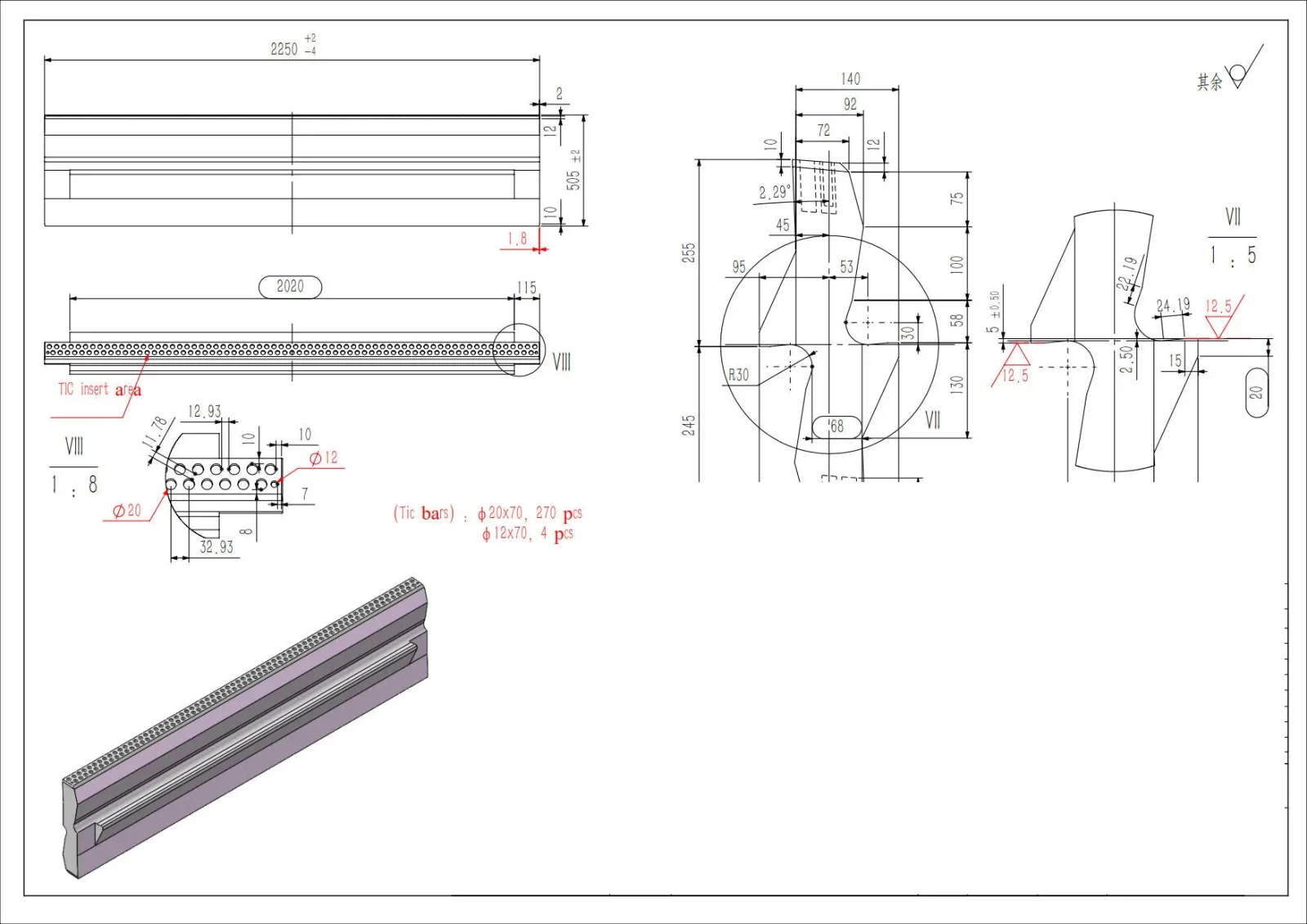

6-piece blow bar sets, each weighing 835kg

- SiO₂ 6%-7%

-

Original OEM parts lasting only 30 weeks per set

-

24-hour downtime for each replacement event

-

4-person maintenance team required for changeouts

-

Significant production losses during maintenance windows

The Engineering Challenge: Beyond Conventional Solutions

Traditional approaches to extending blow bar life had proven insufficient. The client needed a solution that would:

-

Dramatically extend service intervals beyond industry standards

-

Maintain crushing efficiency and product quality

-

Reduce the substantial labor and downtime costs

-

Withstand the extreme impact and abrasion of primary crushing

In-Depth Analysis: The Raw Material Physics and Mechanical Properties

In the cement production process, the physical and mechanical properties of raw materials directly determine the efficiency and cost of crucial stages such as crushing, grinding, and conveying. Limestone with a silica (SiO₂) content of 6-7%, due to its high quartz content, exhibits the following distinct characteristics:

Extreme Hardness and Abrasiveness

-

Mechanism: Quartz has a Mohs hardness of 7, which is more than twice that of calcite (Mohs hardness 3), the primary mineral in limestone. These hard quartz particles act like countless microscopic “files” uniformly distributed within the material mass.

-

Impact on Cement Production:

-

Low Los Angeles Abrasion Value: This is an international standard measure of aggregate abrasion resistance. This type of limestone typically has a very low LA Abrasion value (e.g., <25%), indicating its high inherent resistance to wearing down. However, in a cement plant context, our primary concern shifts to its reverse abrasive effect on equipment, rather than its own wear resistance.

-

High Compressive Strength and High Brittleness

-

Mechanism: Quartz particles act as a “reinforcing phase” embedded within the calcite matrix, enabling the material to withstand higher pressures. Simultaneously, quartz is a typically brittle mineral, and the interface between quartz and calcite represents a mechanical weak point.

-

Impact on Cement Production:

-

Crushing Characteristics: In compression-based crushers like impact crushers, it is more prone to brittle fracture, generating a higher proportion of flaky or sharp-edged particles. This differs from the “plastic extrusion” that might occur with pure limestone.

-

Grinding Characteristics: During the grinding process, cracks tend to propagate preferentially along quartz particle boundaries. However, once a certain fineness is reached, the hard quartz particles themselves become difficult to pulverize further, becoming a “bottleneck” in the grinding circuit.

-

Very Poor Grindability

-

Mechanism: Grindability indicates how easily a material can be pulverized. The presence of quartz significantly increases the resistance to grinding.

-

Quantitative Indicator:

-

Bond Work Index: This is a core parameter for grinding circuit design in the industry. The Bond Work Index for this type of limestone is significantly high (typically in the range of 16-18 kWh/t or even higher), whereas for pure limestone it might be only 10-12 kWh/t.

-

-

Direct Impact on Power Consumption: The raw meal grinding system is a major consumer of electrical power in a cement plant. Using high-silica limestone directly leads to a substantial increase in the specific power consumption of the raw mill, representing a significant burden on the plant’s operating costs.

Solution: Strategically Breaking the Wear Cycle

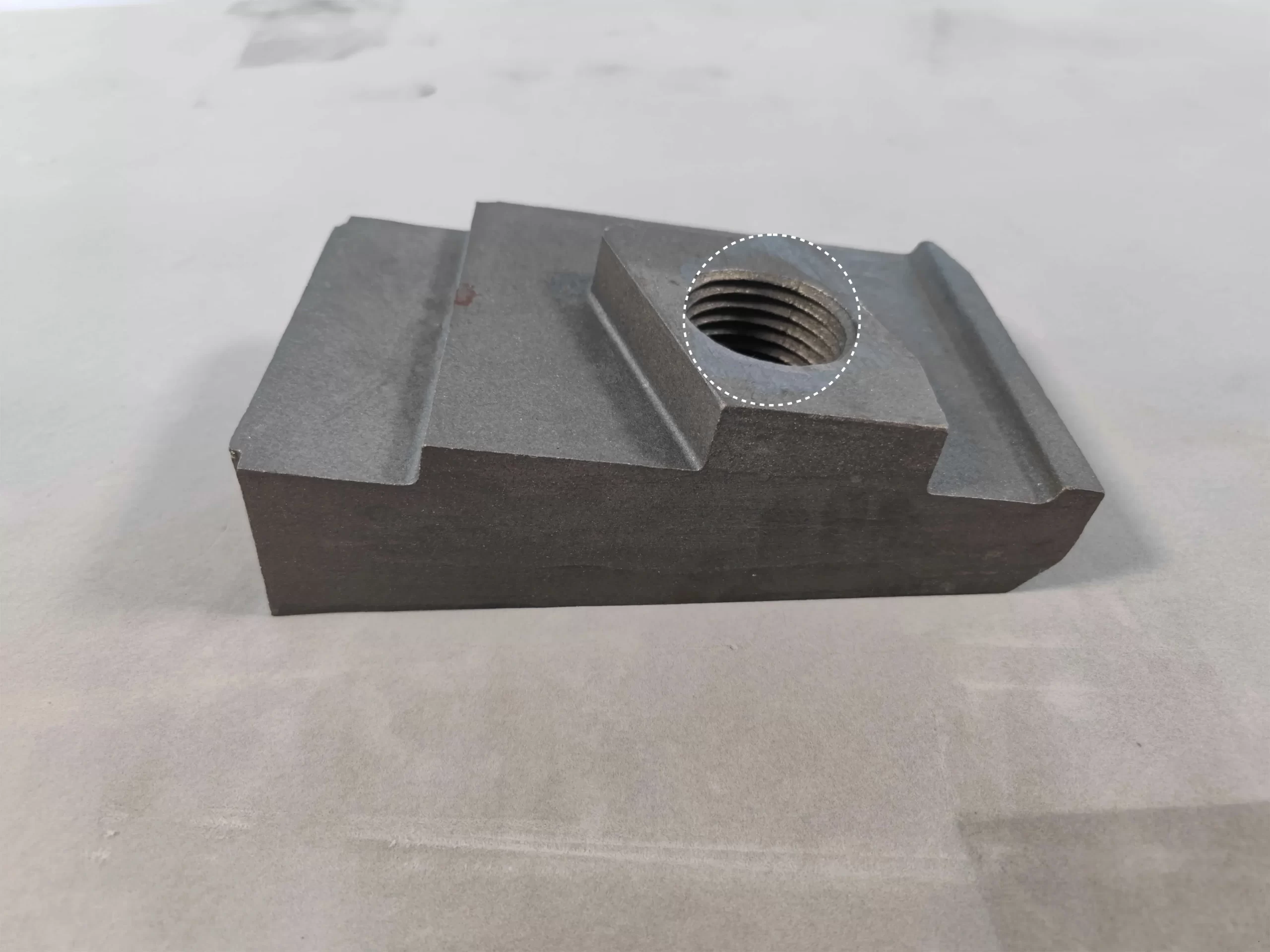

Our TIC-embedded blow bars were engineered to disrupt this destructive cycle at its core.

-

Combating Abrasion: The Titanium Carbide (TiC) rods, with a hardness exceeding 3000 HV, are far harder than any silica or other abrasive particles in the feed. They form an ultra-wear-resistant “armor” that resists micro-cutting and grinding, dramatically slowing the primary wear mechanism.

-

Combating Impact Fatigue: The specially formulated Mn18Cr2 base matrix, enhanced with Molybdenum, provides exceptional toughness and impact fatigue resistance. This ductile base absorbs the massive shock loads, prevents the initiation and propagation of cracks, and securely holds the TiC rods in place. This directly addresses the brittle fracture failure of competitors’ solutions.

-

Synergistic Effect: The system ensures that the tough matrix handles the impacts, while the hard TiC rods handle the abrasion.

Performance Results: Exceeding All Expectations

The implementation of Qiming Casting’s TIC-embedded blow bars delivered transformative results:

Service Life Metrics:

-

Previous Performance: 30 weeks with OEM parts

-

Qiming Solution: 65 weeks of continuous operation

-

Improvement: 117% longer service life

Operational Impact:

-

54% reduction in replacement frequency annually

-

Significant downtime reduction from 24 hours to fewer changeouts

-

Labor cost savings through reduced maintenance requirements

-

Consistent crushing performance throughout service life

Client Testimonial

“The performance improvement has been remarkable. Qiming Casting’s blow bars have not only doubled our service intervals but have also provided consistent, reliable performance. The reduction in unplanned downtime has significantly improved our production planning and cost control.”