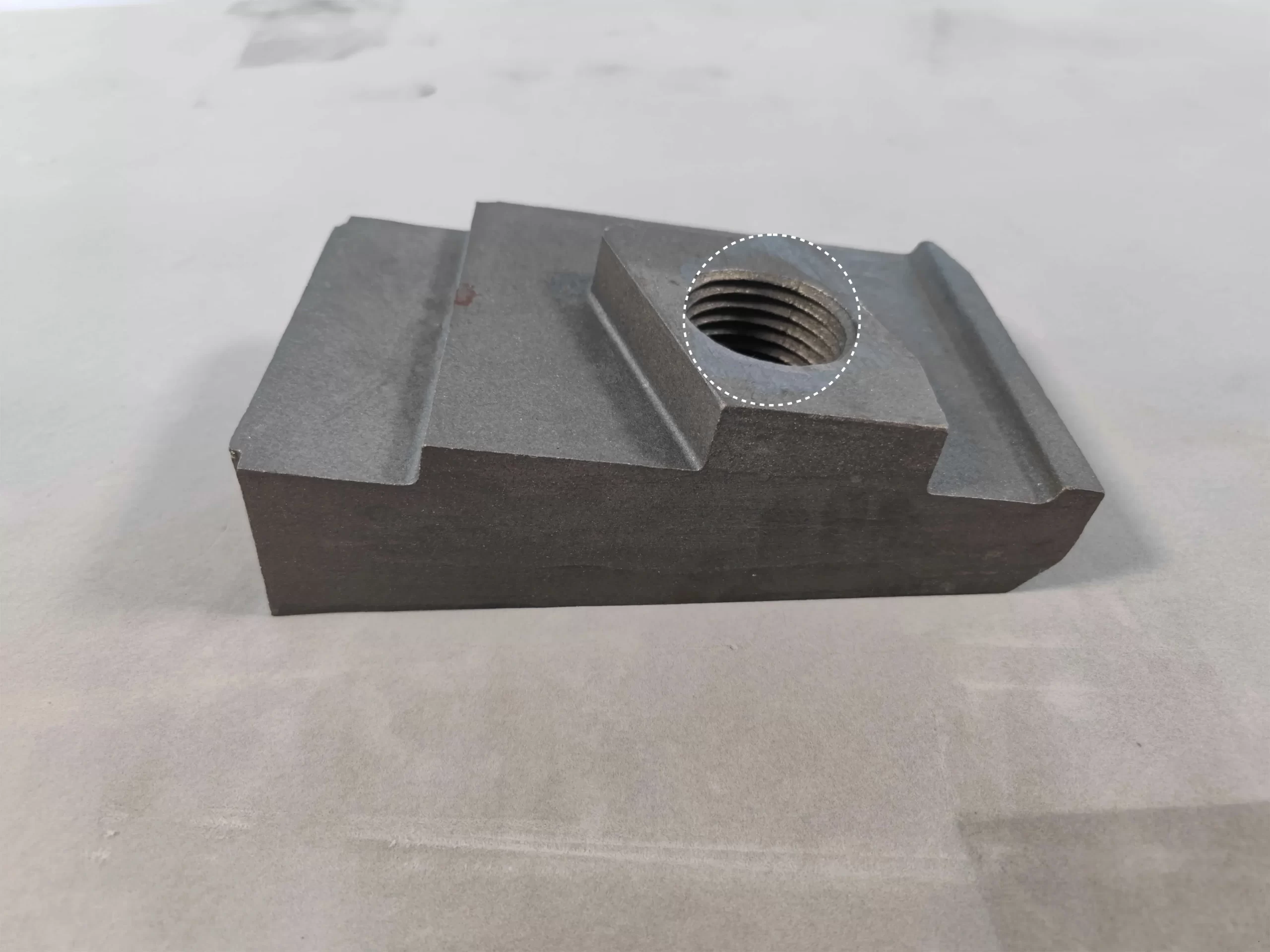

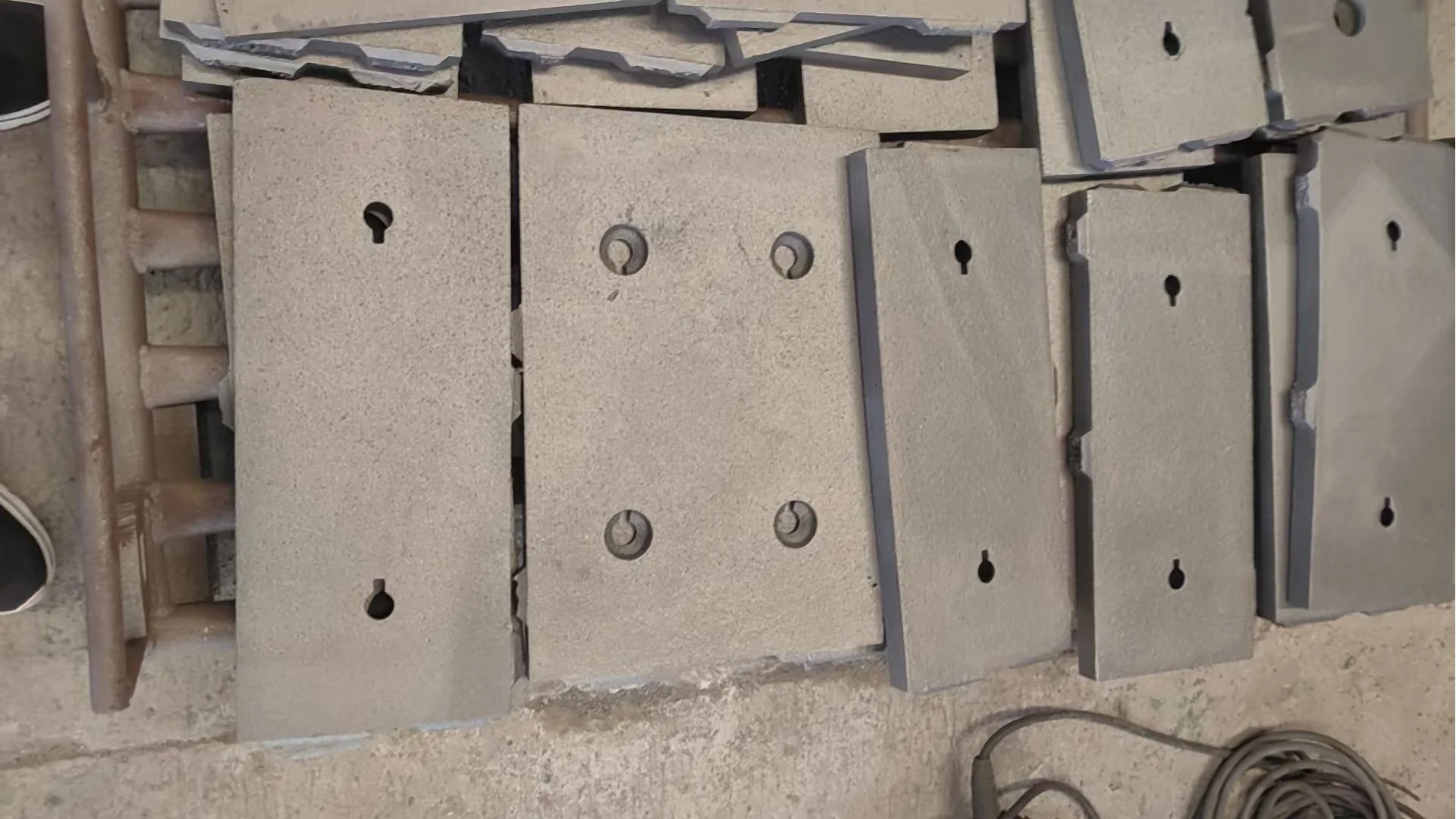

For one frustrating month, our European client’s production line faced costly disruptions. Each newly cast 18mm manganese steel plate emerged from their foundry with surface cavities resembling smallpox—ugly, irregular foam slag defects that scrapped 65% of their premium wear-resistant components. When their engineers hit a dead end, Qiming Casting’s R&D team stepped in. What followed was an eight-week engineering marathon that didn’t just fix a defect—it redefined precision boundaries for thin-section evaporative pattern casting.

The Crucible: Why Foam Slag Defects Target Thin Manganese Plates

Foam slag defects form when trapped residues from vaporized foam patterns interact with molten metal flow dynamics. For sections under 20mm, three factors converge catastrophically:

-

Rapid Solidification: Thin walls cool before slag can float to risers, freezing impurities mid-section34.

-

Manganese’s Reactivity: Mn alloys actively bind with carbon residues from polystyrene decomposition, creating tenacious Mn-C slags16.

-

Incomplete Gas Evacuation: Narrow cavities hinder gas escape through coatings, increasing backpressure that traps particulates28.

Traditional remedies failed spectacularly. Higher pouring temperatures induced carbon pickup6. Thicker coatings impeded venting. Even modified gating merely redirected rather than eliminated slag.

Breaking the Cycle: Qiming’s Four-Pronged Solution

Phase 1: Material Science Overhaul

We replaced conventional expandable polystyrene (EPS) with co-polymer foam patterns. Unlike EPS’s granular disintegration, co-polymers undergo “zipper-like” decomposition—vaporizing instantly into smaller, less reactive gas molecules that permeate coatings 40% faster24. Pattern density was reduced to 22g/cm³ (strength preserved via cross-linking additives), slashing gas volume by 30%.

Phase 2: Dynamic Gating & Slag Trapping

Simulations revealed that turbulence in bottom-poured systems pushed slag toward thin zones. Our redesign:

-

Hollow sprue with ceramic filters dampened flow shocks while filtering >92% of macro-slag.

-

Tilted pouring (15°) maximized vertical surface area, creating natural “escape channels” for rising gases.

-

Foam-filled slag collectors were embedded near plate edges—acting as vacuum pockets drawing impurities before metal solidification. Post-casting, these are simply machined off.

Phase 3: Nano-Enhanced Coatings

Standard coatings choked gas outflow at <20mm thickness. Our reformulation blended:

-

Aluminosilicate microspheres (45–75μm) creating permeable pathways

-

Colloidal graphite preventing metal penetration without blocking pores

-

Antimicrobial additives countering summer humidity-induced fermentation

Controlled at 1.8–2.0mm thickness, permeability tripled to 28 (cm/min)·atm⁻¹.

Phase 4: Precision Thermal Protocol

Balancing heat was critical. We implemented:

-

1580–1600°C pouring temps (30–50°C above sand casting norms), ensuring complete foam vaporization

-

Real-time IR monitoring to adjust pour rates matching gasification speeds

-

Localized sand cooling fins accelerate solidification at slag traps before plates

Results: From Crisis to Competitive Edge

Within 20 days, defect rates plummeted from 65% to 0.8%. But beyond statistics, three transformations emerged:

-

Performance Gains: Impact toughness rose 18% as voids ceased initiating cracks.

-

Cost Control: Per-unit energy dropped 40% by eliminating rework.

-

Design Liberation: Clients now cast 14mm plates previously deemed “unmanufacturable.”

For the European partner, this translated to €380K annual savings and regained market share in cement plant wear-part contracts.

The Core Lesson: Precision Through Interdependence

No silver bullet solved this. Victory came from orchestrating interactions:

“The foam collector means nothing without the coating that lets gases through. The coating fails without temperature-controlled gasification. The temperature is wasted without turbulence-free filling. It’s a system—not a step list.”

— Qiming Casting Process Lead, Liu Yang

Today, these plates withstand 12-month abrasion in German quarry crushers without structural flaws. And that hard-won interdependence? It’s now encoded in every Qiming casting—from 10-ton crusher jaws to paper-thin alloy shims.