Analysis Problem:

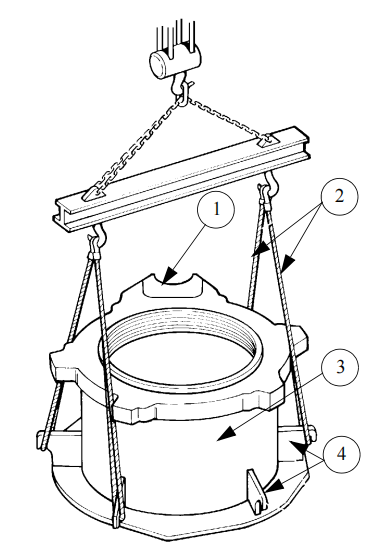

The bowl mantle or liner detachment can occur due to several reasons, including:

1. Incorrect thread torque of the nut’s locking bolt, and the play between the screw’s head and the locking nut is not correct.

2. The locking nut is positioned incorrectly on the spacer ring.

3. The locking nut knocks against the top of the head.

4. Liner/mantle or head spans are damaged.

5. Insufficient play for the seal between the mantle and the head.

6. Cylindricality defect.

7. The mantle is not secured to the head.

8. The mantle is not centered on the head.

9. The mantle rotates too long without feed.

10. The mantle is too thin.

11. The old sealant resin was not entirely removed before installing the new mantle.

12. The tightening lugs of the bowl liner touch the outer diameter of the liner.

13. The bowl liner is too thin.

14. Too much tramp iron passes through the crusher.

15. The span on the bowl liner or bowl is damaged.

16. The old sealant resin was not entirely removed before installing the new bowl liner.

Corresponding Solutions:

1. Apply the correct thread torque.

2. Change the locking nut.

3. Keep a play between 6mm to 10mm between the bottom of the locking nut and the top of the head.

4. Remake the spans.

5. Maintain a play between 6mm to 10mm.

6. The gap between the bottom of the mantle and the gauge should not exceed 0.1mm.

7. Dismantle the mantle and reinstall it correctly.

8. The maximum time without feed should not exceed 30 minutes.

9. Wear should not exceed 2/3 of the mantle.

10. Remove all the old sealant resin.

11. Wedge the lug or tighten the screw.

12. Wear should not exceed 2/3 of the bowl liner.

13. Too much tramp iron will loosen the bowl liner.

14. Remake the spans to the original dimensions.

15. Remove all the old sealant resin.

Ensure that the above solutions are implemented correctly to prevent any future detachment issues.

Download Brochure

Download Brochure Product List

Product List